Elbow Grease Results in Higher Payout for Recyclable Metals

If you’re in the market to recycle metals here in Los Angeles –or pretty much anywhere else—the metal springs in biggest cash pay out is copper. As we’ve written at nausea before, copper comes in so many forms it’s not funny. Bringing a truck load of copper pipes to scrap metal dealer is going to result in a hefty payout. But let’s not forget plumbing’s cousin, the area of electricity and specifically copper wire.

We recently wrote about dismantling old airplanes for scrap, including miles and miles of Copper wire inside the fuselage. Where ever you find it I’m With her in an airplane, construction site for your own home 99 times out of the hundred you’re going to be dealing with coated wire. The Plastic sheathing surrounding copper wire that passes electricity through it and runs everything from your dishwasher television set keep those wires safe. It also makes it a little more difficult to recycle these copper wires because that plastic coating has to be removed so the metal can be melted down and turned into something new.

If you bring a lot of coated copper wire scrap buyer like TM scrap metals here in Sun Valley we will give you a great price but it will be less then a uncoated copper wire simply because more effort goes into removing coating. Of course we’re well prepared to do that. It just takes extra time and effort. However, if you want to increase the payout you receive when you bring your scrap metal to us, if you just invest a little time and elbow grease, you can strip those wires yourself.

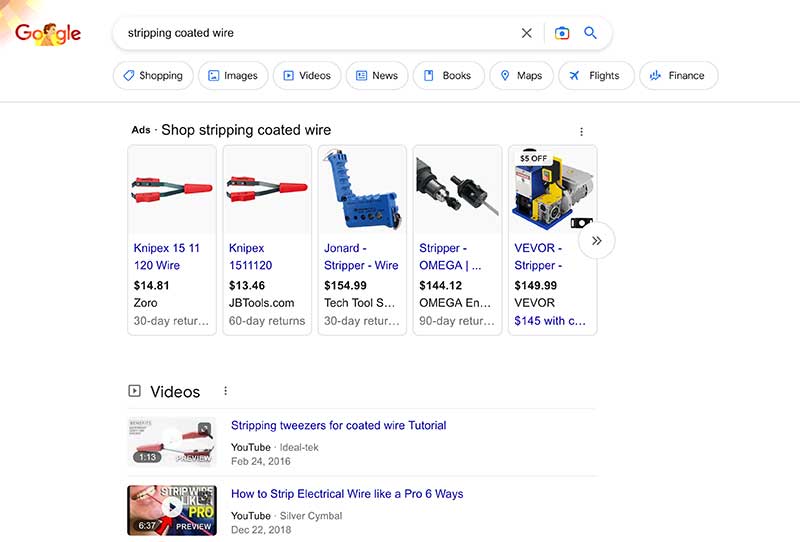

Doing a quick search on Google for wire stripping brings up all sorts of gadgets and tools for completing this process. If you’ve ever done any electrical work—and who hasn’t of one point in their life–you probably used a wire stripper to remove Half inch or more the coating to wrap the bare wire around the white fixture or socket. But using one of those tools to remove the coating on miles and miles of copper wire is going to drive you insane. That’s why there are hundreds of different tools, and many automated, that will help you quickly and efficiently remove the plastic coating from copper wire.

This is a popular pastime especially seasoned scrap veterans so there are many articles that you can read accommodations for which tool works best. You can Check out this article on Bob Vila’s website as an example. Depending on how much work you wanted yourself can strip wire manually are investor hundred to 500 for a wire stripping machine. Spending that amount of money only makes sense if you have ton– Literally–of Coated wire. It was just a little bit there are cheaper tools on the market to help you extract that precious copper wire from its plastic jacket.

As we said you can bring it to us coated or spend a little Time and effort movie coating for a larger cash payout from Scrap metal recycling center.